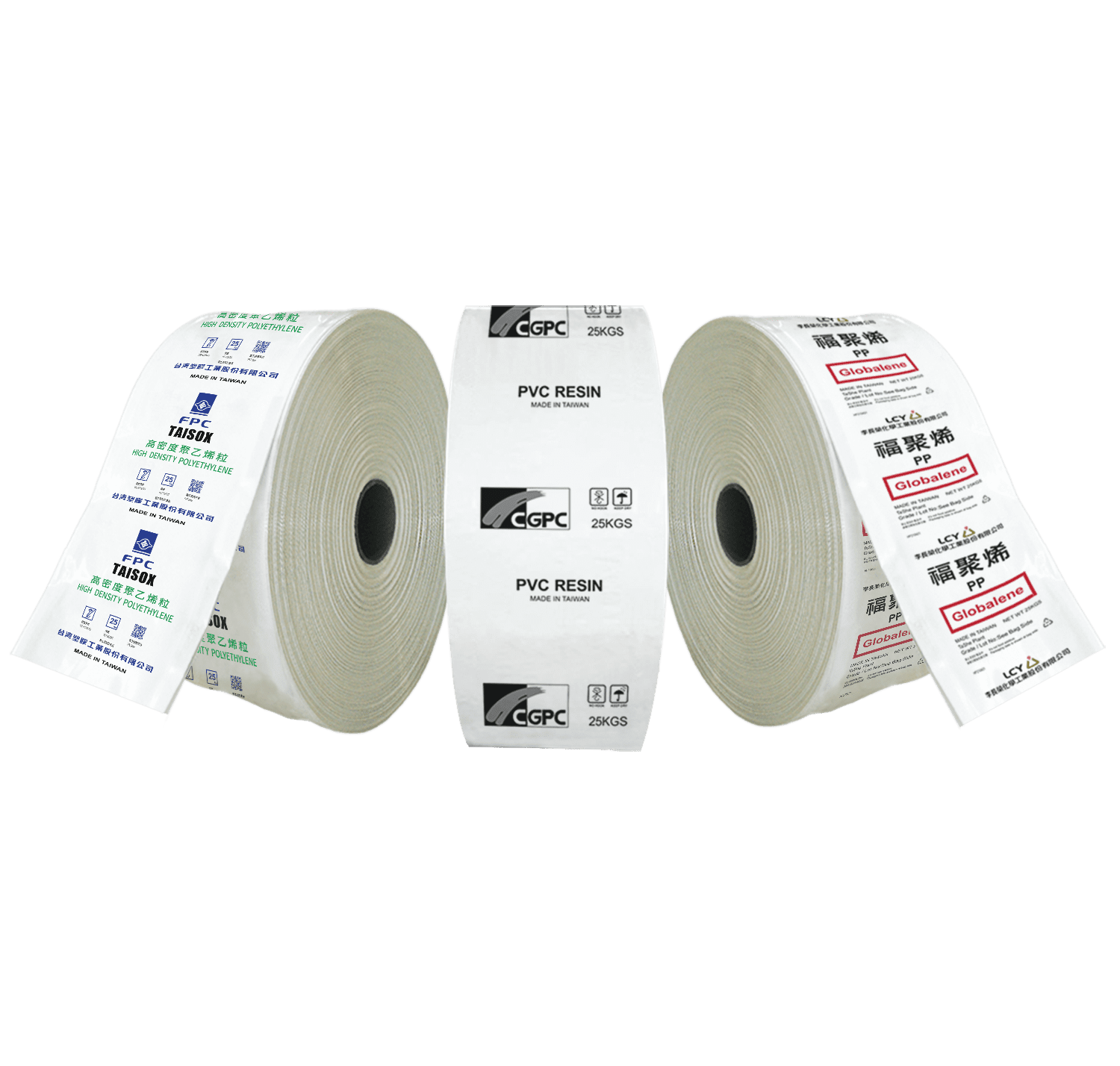

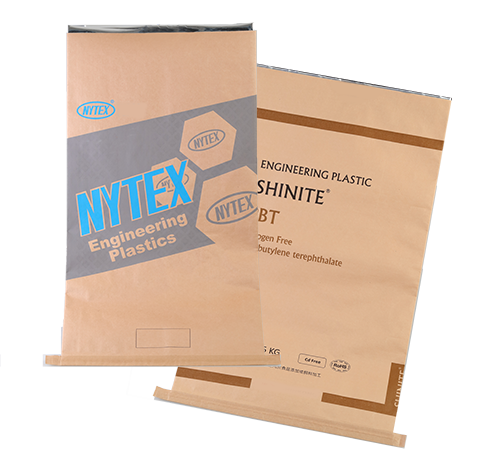

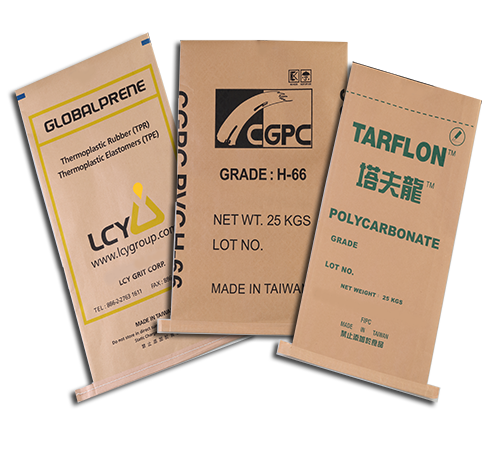

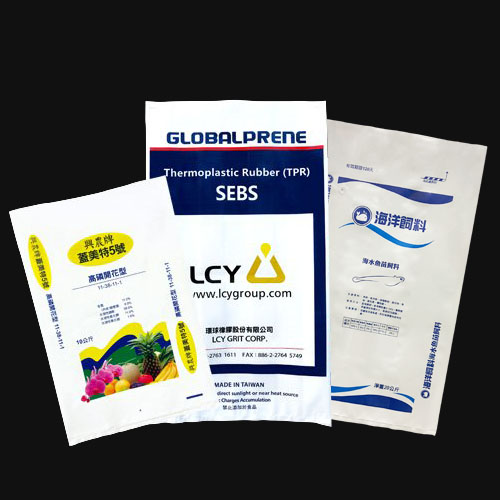

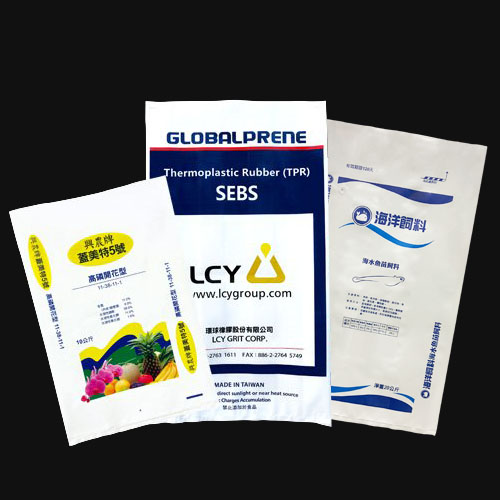

Heavy-Duty PE Bag

Product Introduction :

Heavy-duty PE(Polyethylene) bags have high durability and good thickness uniformity because they were manufactured with high performance polyethylene (PE) material through an advanced multi-layered co-extrusion blown film process.

This product is for clients who want bags with high-quality printed exterior appearance that are leak-proof and have high packaging efficiency. This bag is made of single material and can be directly recycled.

※Applicable to industrial use: Plastic material, chemical raw material, chemical fertilizer, organic compound fertilizer

Heavy-Duty PE Bag

Specification

| Width: | 38~65 cm |

| Thickness: | 0.10~0.25 mm |

| Length : | 50~110 cm |

| Printing: | 1~6 colors |

| Anti-slip Treatment: | Static Friction Coefficient > 0.6 |

| Ink: | comply with Restriction of Hazardous Substance (RoHS) inspection standard |

| Bag material: | comply with “ Sanitation Standard for Food Utensils, Containers and Packages” Single material and can be directly recycled. |

Customizing Options

| ◎Bag Type:Flat type/Gusseted type | |

| ◎Anti-Slip embossing strip | |

| ◎Pinhole degassing | |

| ◎UN Certificate |

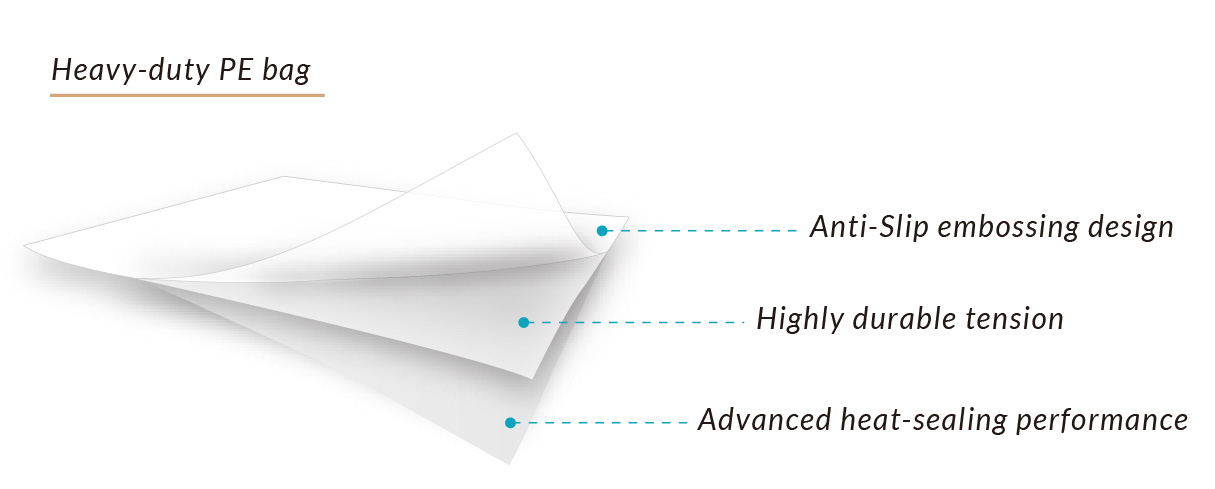

Product Feature

| 1. Bag Type: | |

| Flat type / Gusseted type |

| 2. Anti-Slip embossing strip: | |

| Increase stability during stacking by two anti-slip embossing strips on both sides of bags. (front & back). |

| 3. Pinhole degassing: | |

| After perforating several rows of pinholes on bags, can make bag degassing and have high efficiency during packaging operation. Suitable for Granular materials or products. |

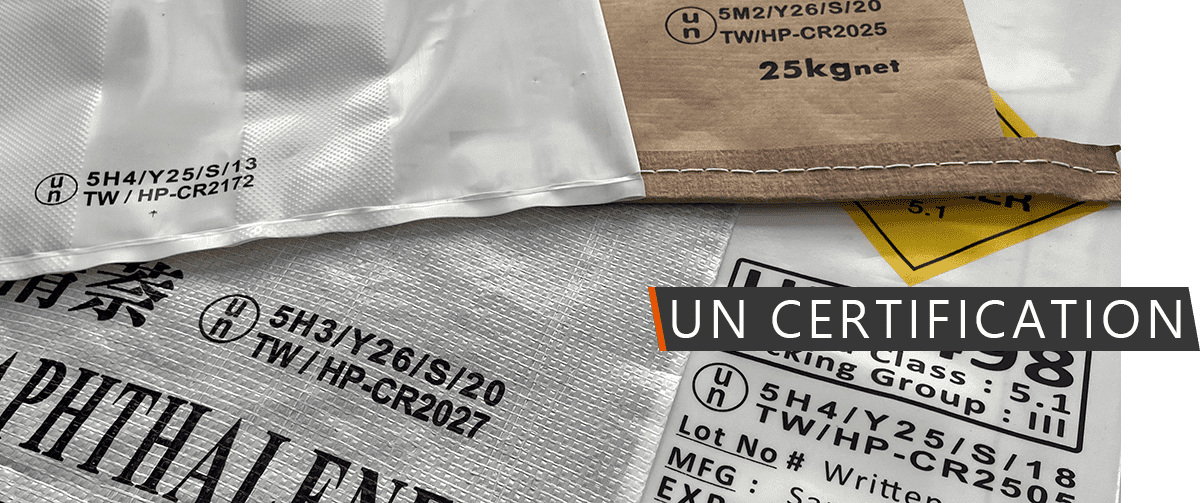

| 4. UN Certificate: | |

| Comply with International Maritime Dangerous Goods (IMDG) Code inspection standard and apply UN certification for client’s bags. |

| 5. One-way degassing valve: | |

| Patented specialized structure to exhaust air quickly from bags during packaging to increase efficiency. |