-

About

About

HOMPAK Introduction

Quality Assurance ,Value Creation

HOMPAK Packaging Inc. has been headquartered in Taiwan since its foundation in 1981. The business philosophy is quality assurance and value creation. Based on three core values – integrity, professionalism, and enthusiasm, provide clients with highest quality products and service. We are committed to our customers and solve packaging problems with great passion to become a trustworthy partner and have an excellent reputation.

With our factory’s complete vertically integrated production lines and decades of experience in customizing heavy-duty packaging, we can provide our customers with comprehensive and professional consultation on material choice and create prototypes for testing.

Leading Technology

HOMPAK is one of the Taiwan leading company in Heavy Packaging Industry

We have implemented the ISO-9001 Quality Management System Standard, ISO-22000 Food Safety Management Standards , and completed ERP enterprise resource integration system. This allows us to become an important link in customers’ packaging quality and food safety control.

HOMPAK received customer’s recognition based on stable product quality and flexible delivery service. Some of our clients are BASF, Covestro, Formosa Plastics Corp., Formosa Chemicals & Fibre Corp., LCY Chemical Corp., Uni-President Enterprises Corp. and Lien Hwa Milling Corp…etc.

CAPABILITY SERVICE

Business

IQC

Fabric

Blown Film

Laminating/Coating

Converting/Tubing

FQC

OQC

Graphic Design

Extrusion Tape

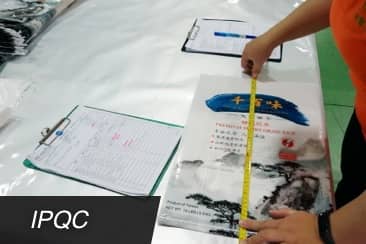

IPQC

Printing

PQC

Sealing

Packaging

Transportation

Factory Introduction

SHA-LU Headquarter, Taichung

HOMPAK based its headquarters in Taichung Shalu and directs cross-plant coordination and executes decisions effectively and efficiently through integrating and processing information gathered from customers.

FENG-CHOU Branch, Taichung

In 2019, in order to bring in new manufacturing processes and expand the production capacity, an additional Fengzhou factory was set up in Taichung Fengzhou Industrial Zone.